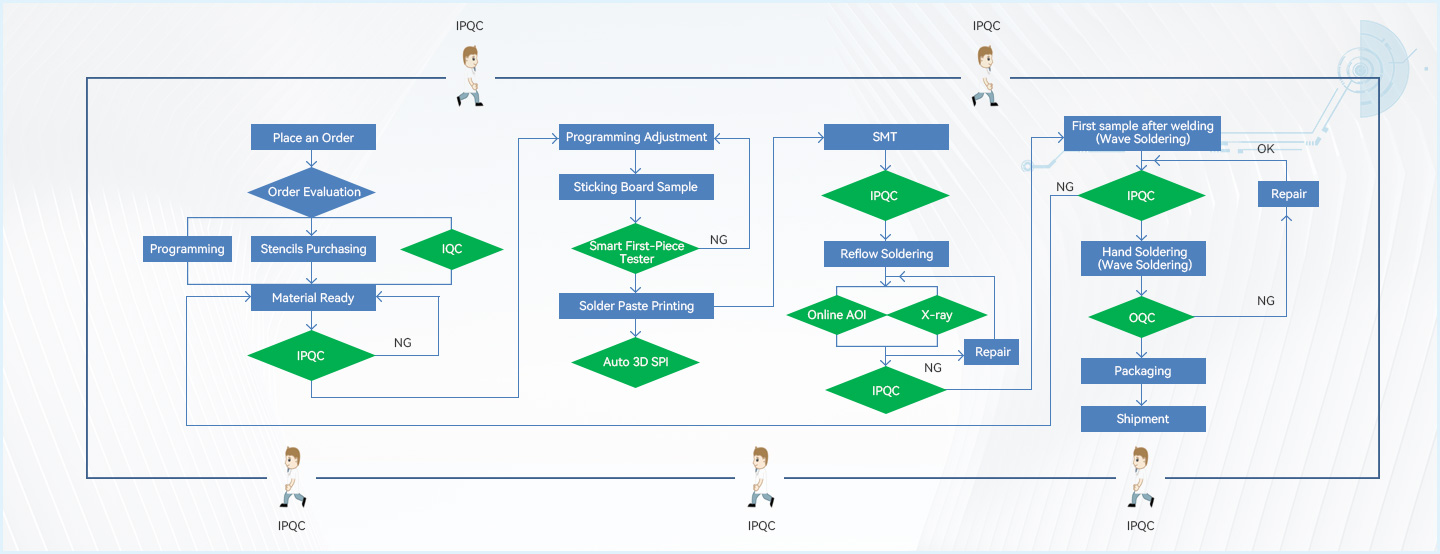

There are currently 6 SMT lines, equipped with new imported Yamaha machine, automatic solder paste printer, SPI solder paste detector, ten temperature zone reflow furnace, Online AOI, X-ray lines and other high-end equipment, with a mounting capacity of 8 million solder joints/day, especially good at high precision, high complexity of the single board, with the production of 40000 + solder joints of ultra-complex single board actual performance.

| SMT Capacity | 8 million solder joints/day |

| SMT Lines | 6 high-speed patch lines, 1 patch proofing line |

| Throwing Rate | Resistance capacitance ratio 0.3% |

| IC type non throwing material | |

| Board Type | POP/Common Board/FPC/Rigid-Flex Board/Metal Base Board |

| Specifications of Mounting Components | Stickable Minimum Package | 03015 Chip/0.35 Pitch BGA |

| Minimum Device Accuracy | ±0.04mm | |

| IC Chip Precision | ±0.03mm | |

| Specifications of Mounting PCB | PCB Size | 50*50mm - 774*710mm |

| PCB Thickness | 0.3-6.5mm |

The new SPI can accurately detect the solder paste printing defects such as excessive/insufficient tin, missing printing offset, etc., to ensure the quality.

Newly updated AOI can accurately detect the mounting problems of components such as wrong parts, missing parts and reverse direction, and the welding quality.

Inspect the solder situation of components, from three-dimensional, like BGA, and reproduce the internal structure in all directions without blind spots.

Test the first sample according to the production data to ensure that the sample quality and function are consistent, and ensure the project promoting smoothly.