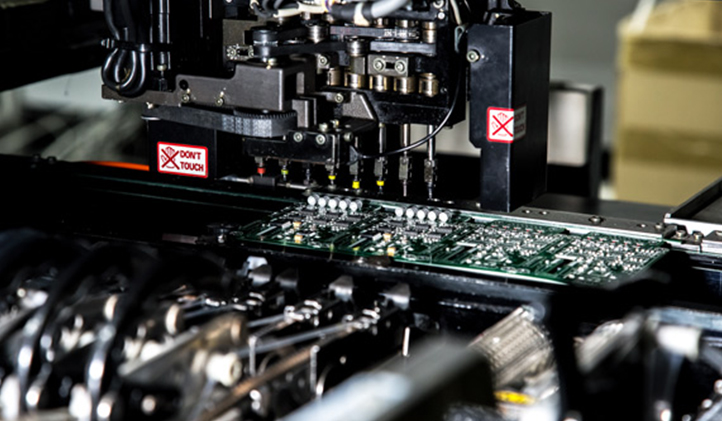

PCB Double-Sided SMT: How Long After the First Side Should the Second Side Be Assembled?

In modern electronics manufacturing, SMT has become the mainstream process for PCB assembly. Particularly for double-sided boards, achieving high-density layouts requires placing electronic components on both sides of the PCB. However, many people may wonder: after the first side has been assembled, how long should one wait before assembling the second side?

Let’s take a closer look. The waiting time before assembling the second side mainly depends on the performance of the solder paste and environmental conditions. Solder paste is the most critical material in double-sided assembly, as it not only secures components on the PCB but also provides electrical connections during reflow soldering. Its activity gradually decreases over time, and prolonged exposure to air can lead to oxidation or moisture absorption, which may affect solder joint quality. In general, for lead-free solder paste at room temperature, the second-side assembly should be completed within about 4 hours, and no later than 8 hours. For leaded solder paste, the window can be slightly longer, but it is usually recommended to finish within 6 hours.

Besides solder paste, the assembly sequence and component type are also crucial. Light and small components, such as 0201 or 0402 packages, are usually placed on the lighter side, while larger or heavier components are recommended to be placed on the bottom side of the PCB to prevent them from falling off during the second reflow. In actual production, the typical sequence is: bottom-side placement → reflow soldering → top-side placement → second reflow. Ensuring that the second side is assembled within the active period of the solder paste can effectively reduce defects such as solder voids, solder balls, or cold joints, improving both yield and product reliability.