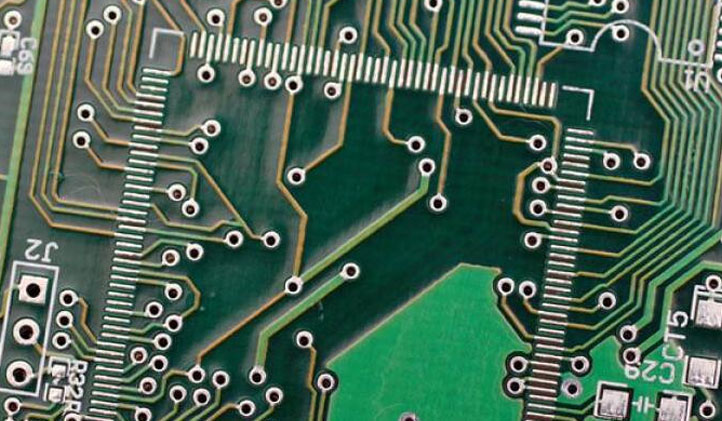

Why Avoid Right Angle Traces in PCB Routing?

In the process of PCB production, the design of the circuit board is a meticulous and time-consuming process that allows no room for error. There's an unwritten rule in PCB design that traces should avoid using right angles. But why is there such a rule? This is not a whim of designers but a carefully considered decision based on multiple factors. In this article, we will unravel the mystery of why PCB traces are advised against taking right-angle turns, exploring the reasons and the design wisdom behind it.

Firstly, let's clarify what right-angle traces are. Right-angle traces refer to traces on the circuit board that form distinct right angles or 90-degree angles. In the early days of PCB manufacturing, right-angle traces were not uncommon. However, with technological advancements and increased requirements for circuit performance, designers gradually began to avoid using right-angle traces, favoring curved or 45-degree angled shapes.

In practical applications, right-angle traces can easily lead to signal reflection and interference. During signal transmission, especially in the case of high-frequency signals, right-angle traces can cause the reflection of electromagnetic waves, leading to signal distortion and data transmission errors. Additionally, the significant change in current density at right angles can cause signal instability, affecting the overall performance of the circuit.

Moreover, boards with right-angle traces are more prone to manufacturing defects, such as solder pad cracks or plating issues. These defects can reduce the reliability of the circuit board and may even result in failures during use. Considering all these reasons, designers avoid using right-angle traces in PCB design to ensure the stability and reliability of the circuit.